|

PENNY BLACK

|

|

THE EQUIPMENT

The most widely played penny game of all |

|

The Principles |

|

The Principles

|

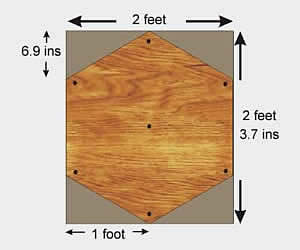

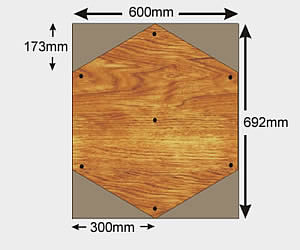

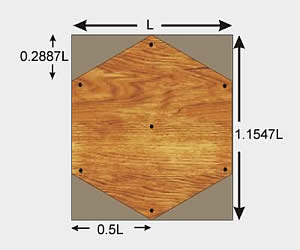

| The board should be flat and polished. Traditionally the shape is a regular hexagon, but square and round boards are also used. The coins should be able to slide easily across the surface of the board and come to a gradual halt. |

|

The Ping Factor

|

|

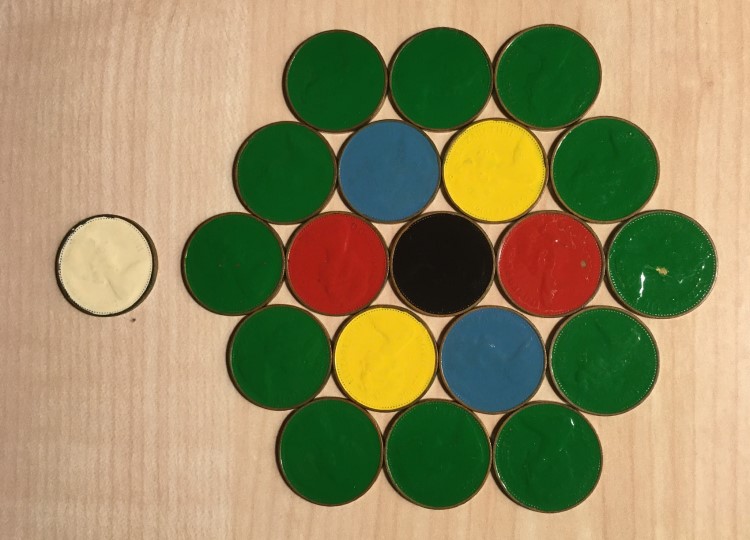

Coins should bounce off each other like snooker balls. In a head on collision between a stationary and a moving coin, the moving coin should come to a sudden halt and the other coin should move off. Hard metal coins will do this. Soft metal coins will not. Hard metal coins are said to have a high ping factor (coefficient of restitution). Coins with a smooth rim are best. Click here

for an animation All the animations on this site were made for PCs. Apologies. Unfortunately, I have lost all my .fla files so can't copy and adapt them for small screens. I will have to make more from scratch. The best set of pennies I had were 7/8 inch stainless chamfered washers. When I went back for some more the guy at the factory apologized and said he shouldn't have let me have the first lot. All those washers were destined for the MOD to use in the chieftan tank. Yes there was a brief time when we played with chamfered washers. (If you want to try washers get the very best stainless chamfered ones you can find.) |